Three students at Leuphana University Lüneburg have discovered agriculture for themselves: Alongside their Bachelor’s degree, they founded the CubeCrops project to supply the urban population with sustainably grown food through innovative vertical farming. Initial sketches of ideas were further developed at the Startup Port start-up camp. In November, the concept was named start-up idea of the year 2023 at the Lünale, the annual award ceremony for successful entrepreneurship in the district of Lüneburg.

The spark that ignited the project was a simple realization: “Joshua and I noticed that the agriculture that supplies us with food every day looks very different from the romanticized image that is so often conveyed,” explains Leuphana student Martin Auer. Conventional, industrial agriculture causes environmental damage through the use of pesticides and pollutant emissions due to long transportation routes. And in the end, incredible quantities of food produced in this way are thrown away because they have already spoiled during the long transportation routes or were produced in excess of actual demand. That’s why the two were looking for a solution to how vegetable cultivation can work with many small, decentralized, local plants.

Concept of CubeCrops: Vertical farming in the city

This is where the principle of vertical farming comes into play. The plants are grown on top of each other in shelves to save space. This allows a higher yield to be achieved in a small area. In addition, vertical farming is usually carried out in controlled growing environments. The plants are supplied with the necessary nutrients via a nutrient solution. At the same time, plant lighting and climate control systems ensure an optimal growing climate. Compared to conventional farming, this enables significantly faster and seasonally adapted plant growth, pesticides can be completely dispensed with and up to 97 percent less water is required.

Challenge and innovation in energy consumption

However, the idea is not new: “There are already companies that use this principle,” says Joshua Biron. “But they are based in the USA, Asia or the Arabian Peninsula.” In Germany and Europe, the concept is not yet so widespread or existing companies with a similar approach have given up in recent months because their business model was no longer profitable in view of rising energy prices. “Above all, there is a lack of resilient business models that work regardless of rising energy prices,” says Joshua. To solve the challenge of high energy consumption, the founding team is pursuing approaches to utilize industrial waste heat and technically improve energy efficiency.

From the Startup Port founding camp to the prototype

These considerations resulted in the first sketches of ideas, which Martin and Joshua used to register for the Startup Port start-up camp in summer 2023. This took place over three days at Hamburg’s Tempowerk technology park. Together with start-up consultants, the individual building blocks of a knowledge-based business idea were put to the test and developed into a mature business model. Canvas models, rapid prototyping and various risk scenarios were used to flesh out the offer, sharpen the target group and check the feasibility and scalability of the revenue model in order to put the company on a solid footing.

The concept, which was revised at the Startup Port founding camp, now involves converting discarded shipping containers so that plants can be grown in them on shelves – ranging from leafy greens and herbs to strawberries or algae. “Leafy greens, i.e. plants whose leaves are harvested for consumption, are particularly suitable for this form of cultivation,” says Joshua. “This makes around ten harvests per year possible. With fruit or vegetables, where you always have to wait until a fruit is ripe, you can’t achieve that many cycles.” In addition, such plants are usually larger and more complex to cultivate. This is at the expense of efficiency in the space-limited containers.

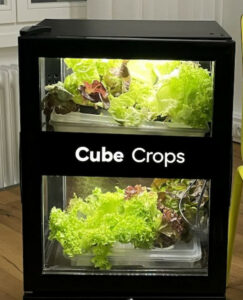

An initial prototype has already been developed. The team’s contacts to the Lüneburg start-up ecosystem were helpful: they found premises for the development of their prototype at “Utopia Lüneburg” and received support in programming a control system at FabLab Lüneburg. A discarded refrigerated display case initially served as a mini container. “We were helped by chance,” says Martin, “one evening when we came out of Utopia into Lüneburg city center, we found the refrigerated display case that someone had just put out on the street as bulky waste. It was ideal for us to use for our experiments in controlled plant cultivation after a small conversion.

Award and attention: success at the Lünale

The award at the Lünale and the subsequent media coverage brought the team some attention. Shortly after the event, medium-sized companies from the region contacted the team, expressing an interest in working together. Collaborations with industrial companies are particularly promising for the team, as the waste heat generated in the plants can be used to heat the facilities, especially in winter. The containers would be set up on the partners’ company premises for this purpose. In addition to energy efficiency, this would have another advantage: the containers would be placed on already sealed surfaces and no new green areas would have to be sealed. At the same time, the cultivation area would be close to consumers, but would not take away any valuable living or recreational space from residents in the inner cities.

Expansion of the team and optimization of the prototype

In the meantime, fellow student Anabel Burchill has joined the team and is working diligently with her colleagues to optimize the prototype. In the meantime, the three are already planning something bigger: initial talks are underway about the purchase and construction of the first real shipping container. In general, however, the construction of the systems is to be outsourced at a later date.

Future plans: Larger containers and community organization

For the founding team, the organization of the community is the focus of the entire concept. Joshua explains: “We’ve taken a lot of inspiration from community-supported agriculture, where the harvest is shared among the participants”. And Martin adds: “With us, the participants regularly receive vegetables from hyperlocal, sustainable and pollutant-free cultivation.”

Anyone interested in supporting CubeCrops with the implementation of a pilot project can contact the team by e-mail: info@cubecrops.de.

Further links: